What is veneer?

When you hear that a piece of furniture is veneered, do you cringe a little bit? That may be because usually the furniture you see that is veneered is made with a material that is not wood at all, it is a laminated material that can be plastic or paper or printed sheets with wood grain patterns that is usually worn around the edges and this is what can influence your perception of veneered furniture but there are real wood veneers that can completely change your perception of veneer for the better.

What are wood veneers?

In simple terms, veneers are thin sheets of natural wood generally less than 1/40" thick. These veneers are often pressed or laminated with thicker core materials, such as plywood, particleboard and MDF, to create structural panels that are used in place of thicker hardwoods. It is still real wood, but machinery and technology allow the material to be cut into thin sheets with no waste, rather than closed up into thick boards. Like thicker boards, it can be sawn flat, quarter sawn, rift sawn or rotary sawn, and produce the different grain patterns associated with each cut.

How is veneer processed?

Veneer is processed in a sawmill in much the same way that hardwood lumber is processed. The veneer logs, which comprise 1 to 2% of all carved logs, first undergo a long period of complete immersion in "vats" of hot water to soften the wood fibers and prepare them for cutting. After this long immersion, the logs are prepared for the cutting operation. There are different methods of slicing, but all involve the process of cutting thin micro slices, called blades, from the veneer logs with a sharp knife. The most commonly used cutting methods are plain sawing or flat cutting, rotary cutting, slitting and quarter sawing/cutting, each of which produces a specific grain pattern. Freshly cut veneer sheets undergo a drying process and are reassembled into bundles composed of all the sheets from the same log in the same order in which they were cut.

Economic and ecological advantages of real wood veneer

There are many advantages derived from using veneer instead of or in combination with traditional hardwood. Using wood veneer is a more cost-effective and efficient use of a natural resource, therefore more environmentally friendly. Compared to a 1" thick hardwood board, veneer cut to 1/40" will provide 40 times more decorative surface area than board. Being a flexible wood, the physical properties of veneer allow for veneering surfaces that would be difficult or even impossible with hardwood. The wide variety of veneers with different cuts offers many more options than are usually available with hardwood. The ability to stain and finish the veneer to your liking is equally important and is no different than with hardwood. The result is a beautiful wood surface with depth, color and unique character.

We hope this explanation will encourage you to use our veneer products. Below you will see the types of veneers we have available for you:

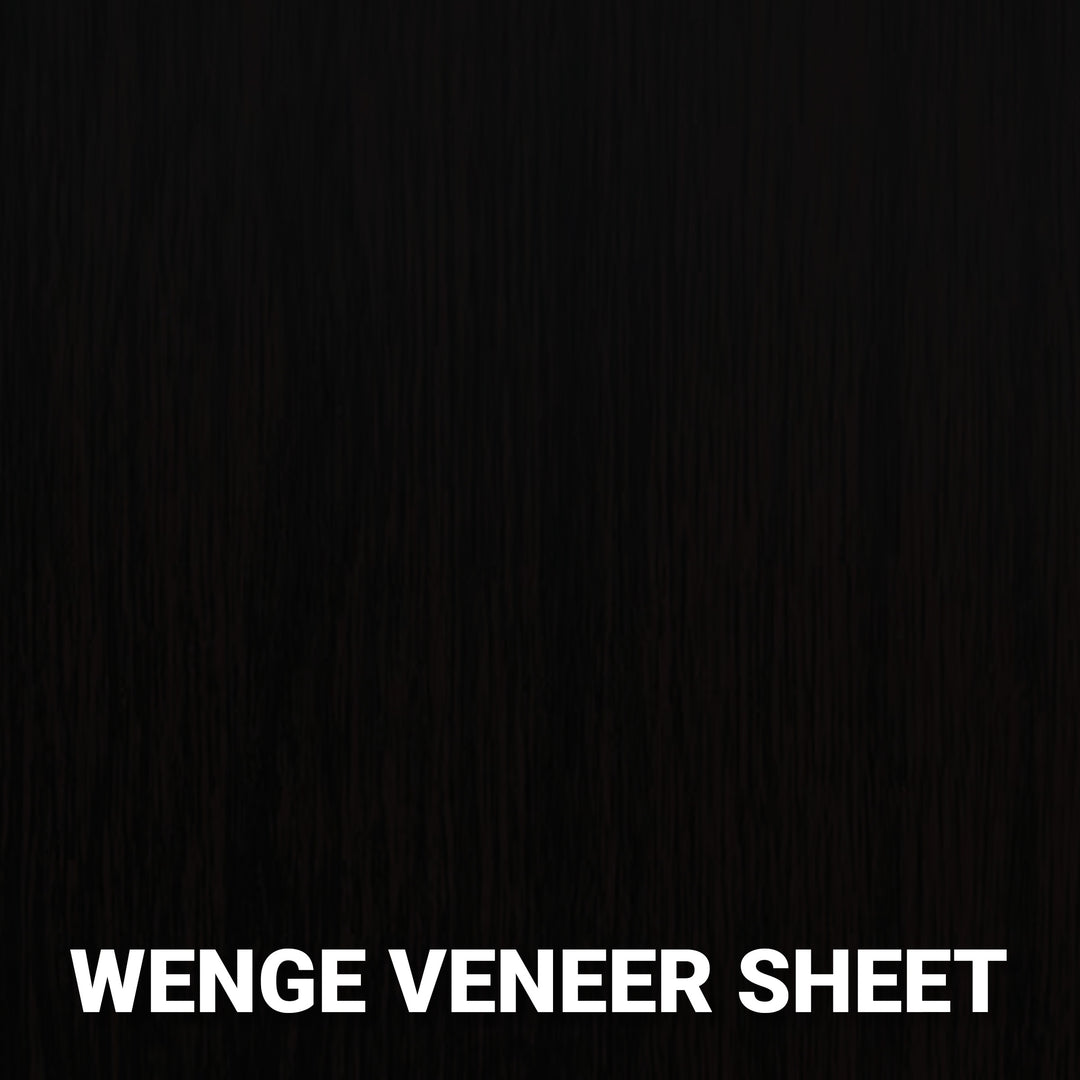

Wenge Wood Veneer

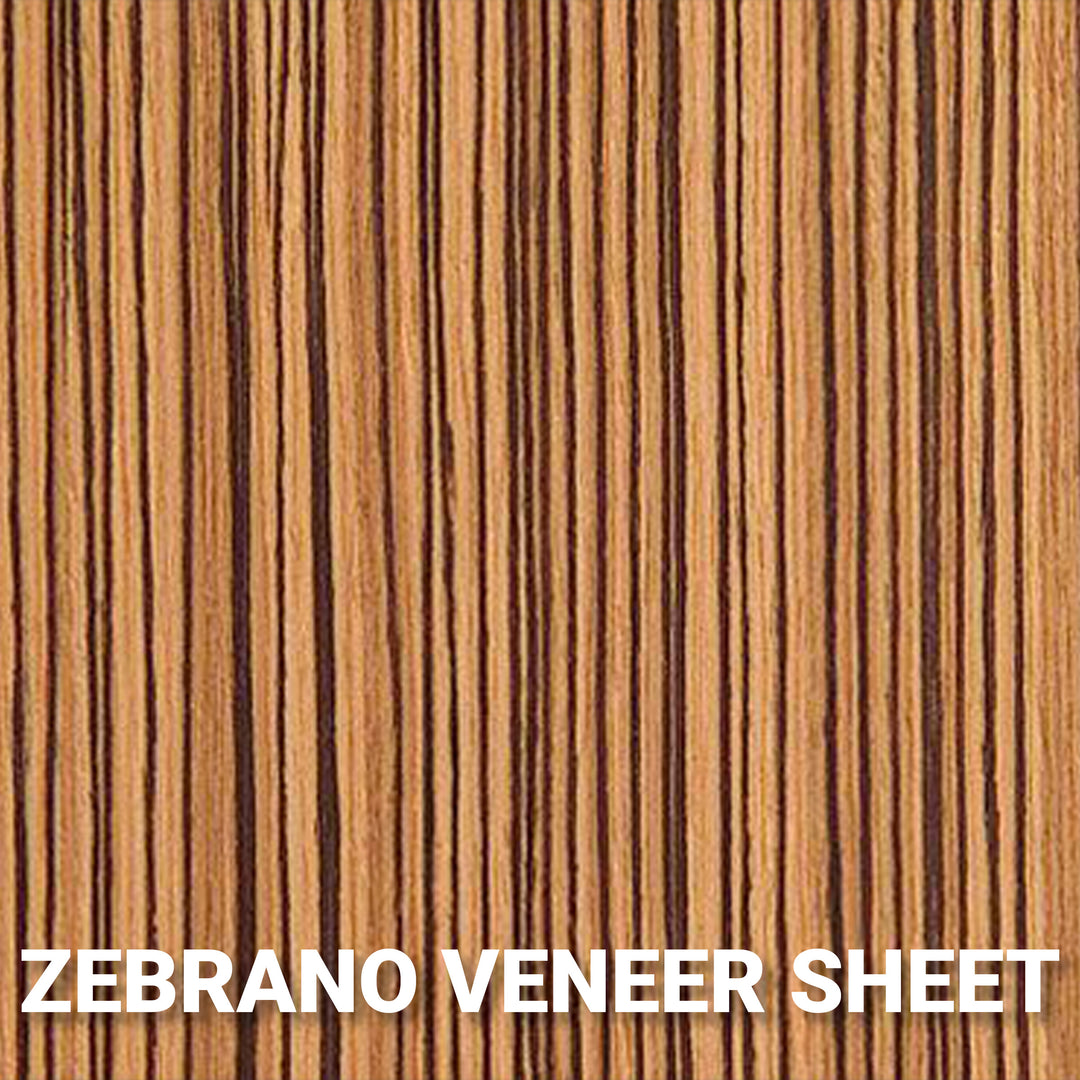

Zebrano Wood Veneer

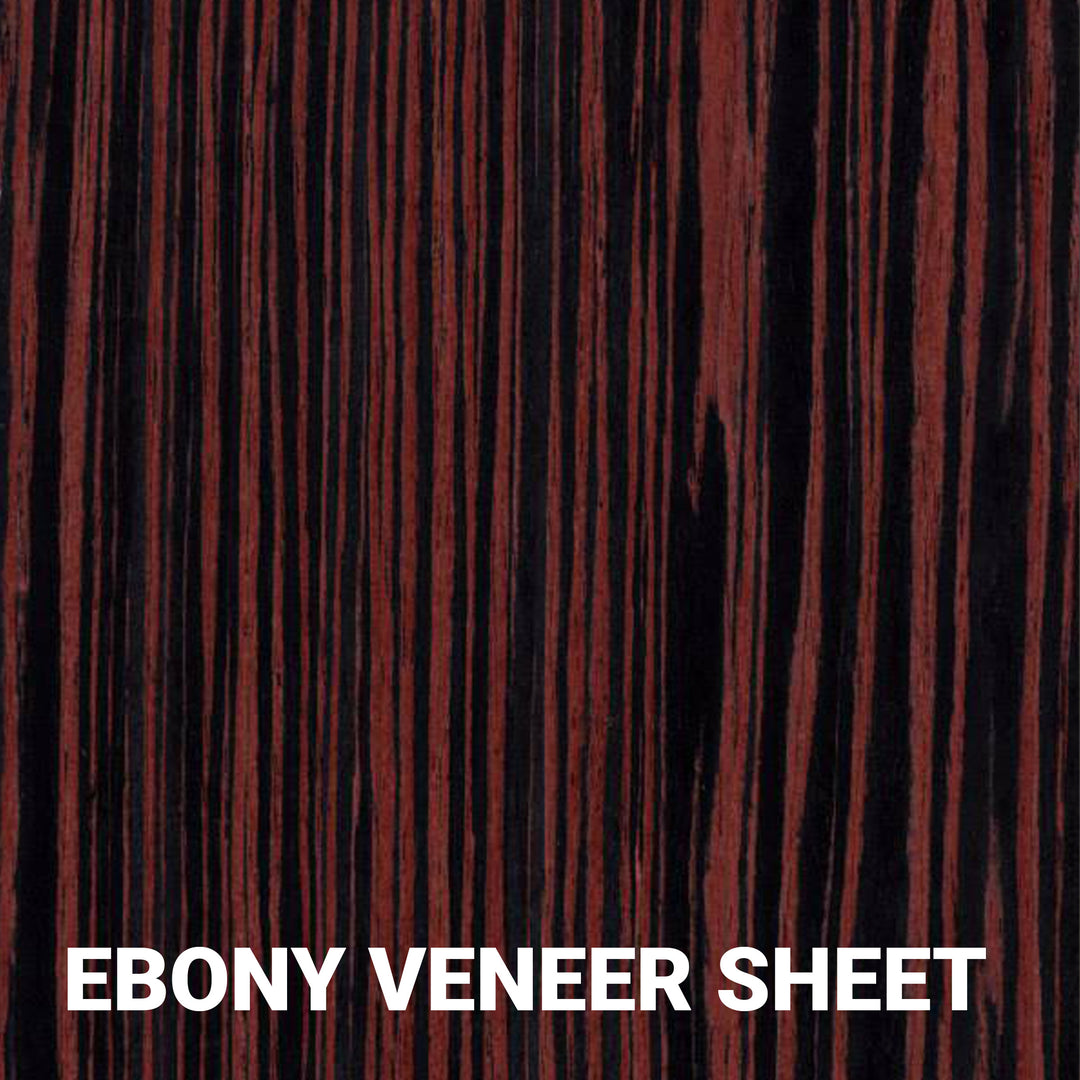

Ebony Wood Veneer

Let us know which veneer you have chosen by filling out the form below or by calling us at +1 (352)-309-6295.